OUR STORY

OUR STORY

Owen carbon is a family brand and an on-line store of carbon motorcycle equipment registered in Slovenia, Europe. Our leading guidelines for research of premium-quality carbon accessories are quality and precision.

Our story began in 1986 when our founder Samo Oven opened his first motorcycle repair and body shop for the following motorcycle brands: Honda, Kawasaki, Suzuki, and Yamaha.

TRADITION

TRADITION

We’ve gained rich experience by cooperating on internationally acclaimed motorcycle competitions, such as Technocorse and Yuraracing, as technical support from 1997 to 2008.

With the advancement of racing technology, the original motorcycle parts needed replacing with something better and lighter, so we’ve developed our carbon fibre parts for motorcycles.

TECHNOLOGY

TECHNOLOGY

We are proud of our 1000 m2 modern workshop with an auto-clave furnace. We produce a large variety of carbon items for the European market and are the sole manufacturer for Lightec – Italian company.

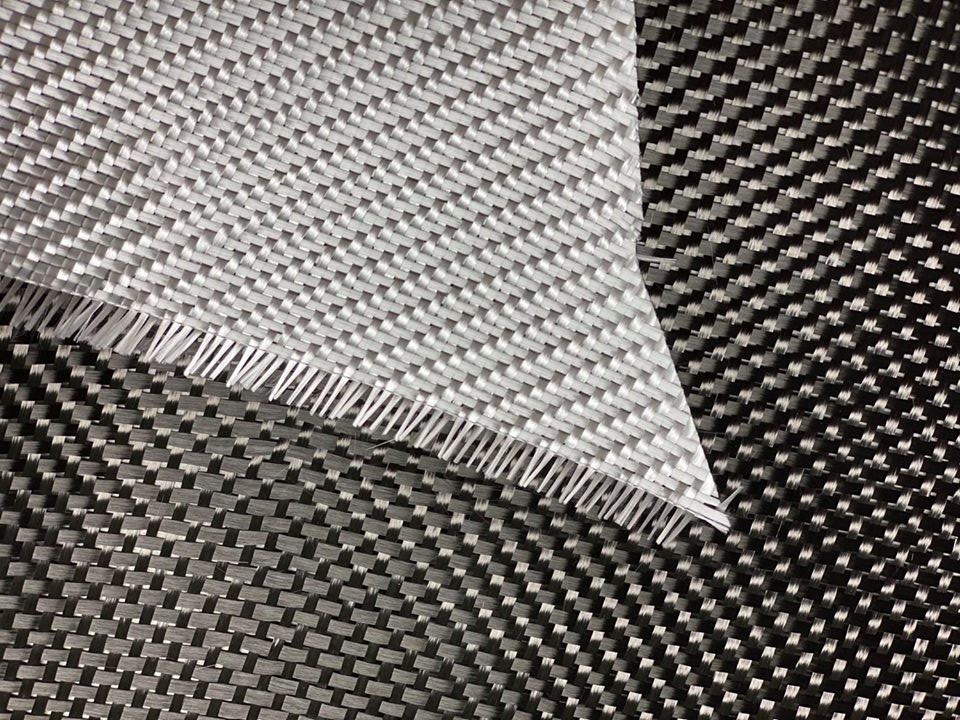

Did you know there’s more than one way to weave carbon?

Plain: 160g – 200g. Plain weave is the most common weave choice, that looks very much like a small grid from your Math notebook. Its main advantage is how simple it is to produce, because there is no chance for the fibre ends to get too entangled.

Twill: 200g – 245g. A particular type of weave in a 2×2 pattern, giving the products a more modern look. Its unique look is what makes it so popular. The weave is also looser, making it more flexible and therefore suitable for more complex shapes.

Autoclave Technology: We use Autoclave technology to compress and harden composite materials, such as carbon. This technology is used worldwide to produce carbon parts for aviation and space technology. During this process, motorcycle parts are dried and compressed in a special chamber at high temperature and under high pressure.

Prepreg: Prepreg is a reenforced fabric, preemptively impregnated with resin, usually epoxy. The resin mixture already contains suitable solidifiers, which makes moulding without additional epoxy possible. We use a combination of heat and pressure to solidify the material. The two technologies, autoclave and prepreg, are therefore tightly intertwined. The equipment needed to complete the process successfully takes years of training, a deep understanding of the techniques and expensive equipment. Unprocessed prepreg has an expiration date which is why it’s stored at -18C.

Carbon Avio Fiber: Avio fibre (epoxy resin) is an excellent alternative to all the standard casings made of glass fibre. It’s lighter, more flexible, and more robust. Our Avio Fiber chassis for motorcycles is reinforced with carbon fibres. The armour is made to high standards, demanded by professional racing teams. They are designed to enable quick setup and replacement.

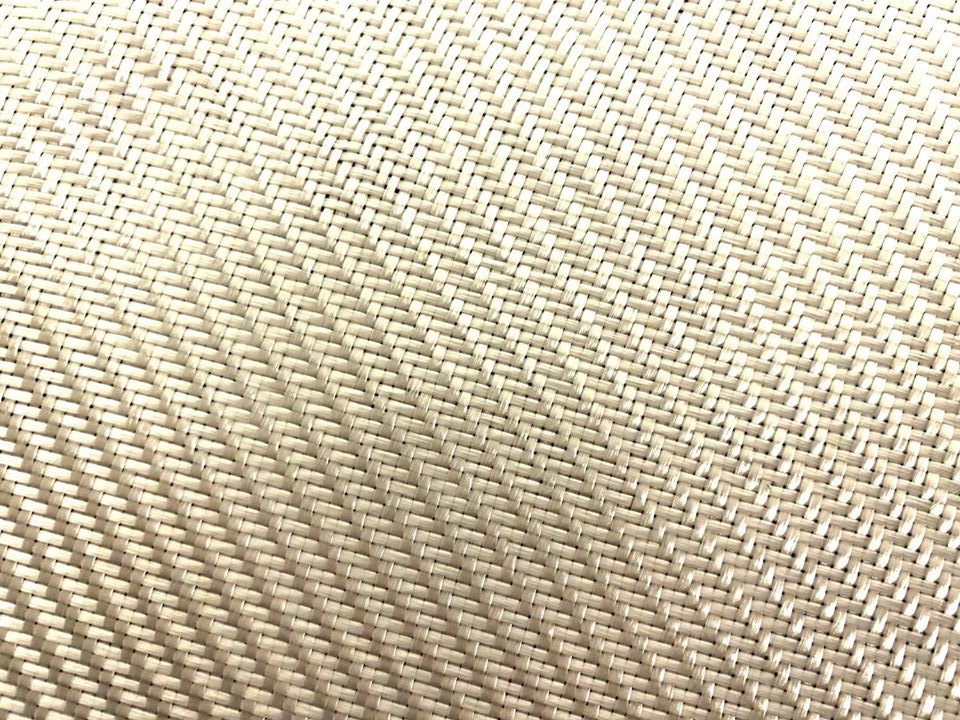

Glass fibre: Glass fibre offers a large application variety. It’s frequently used as reinforcement fibre for polymer resins, such as epoxy and unsaturated polyester. Glass fibres are less rigid compared to other reinforcing materials with high strength and low density, making it a price effective choice as well. Glass fibres will be used as the primary strengthening fibre in the future.

Press technology

Manual lamination: Manual lamination is a traditional technique of placing the carbon fabric inside the mould. It’s a multi-layered composite – its cross-cut looks like a sandwich. Individual layers are thoroughly impregnated with resin. After the impregnation is complete, a heavy roller is used to squeeze out any air bubbles that may have occurred during the layering process.

Press system: Our machine presses shape the metal or resin material using high pressure.

TRUST

TRUST

We supply motorcycle parts for various brands, such as Honda, Kawasaki, Suzuki, Yamaha, Agusta, Aprilia in BMW, Triumph, and Ducati (1998 models and younger).

We can make custom moulds for other brands! We provide a large selection of carbon supplies for the European market, and we’re an exclusive parts manufacturer for Lightech, Italian company cooperating with the Moto 2 Speed Up team.